Today a spectrometric test of materials used for white balancing of reflected UV photography: SPECTRALON (R) calibrated reflection standard made and sold by company LABSPHERE, sintered porous PTFE (porous filter discs, as used in filters for chemical processes and medicine) and virgin white PTFE (white extruded industrial material for various purposes sold as plates, cut discs etc.) to see which of these materials would be suitable for the UV-VIS range of 300 - 700nm. Many years ago I had proposed to use virgin white Teflon (R) / PTFE as a cheap and easy to get material.

[click on image to see a larger one]

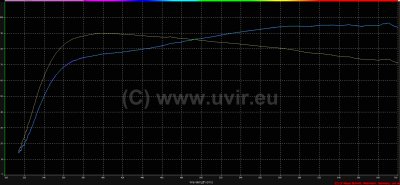

The 100% (green, hard to see) line is the reflection of the SPECTRALON (R) reflection standart as sold by LABSPHERE and is used as a refence. The yellow line indicates the reflection of some seemingly sintered PTFE, now sold as white balance filter mounted into filters rings (52mm in this case), originally made and sold as 50mm porous filter material for chemical and medical purposes. This latter material reflects rather evenly between 80-83%. The virgin PTFE in comparision has a more uneven reflection of 72-75% (>320nm), down to 68% below 320nm. For amateur photographic purposes the two cheaper materials provide sufficient evenness, with an edge in favour of the sintered PTFE. For professional applications, both are however no alternative to the industry standard SPECTRALON (R) which shows outstanding evenness.

Remark: all such materials are extremely sensitive to dirt, fingerprints etc. which reduces the UV reflection massively, so have to be kept clean at all times and need to be cleaned asap if so contaminated. Best to clean is to brush with purified water, a detergent and ethanol, then rinse with purified water, then let dry in a dust and lint free environment or dry with pressured clean air.

Stay tuned, more will follow on that fascinating subject...

More info on this very interesting field may be found on my site

http://www.pbase.com/kds315/uv_photos